Conisbrough Railway Bridge Maintenance

March, 06, 2023

At a Glance

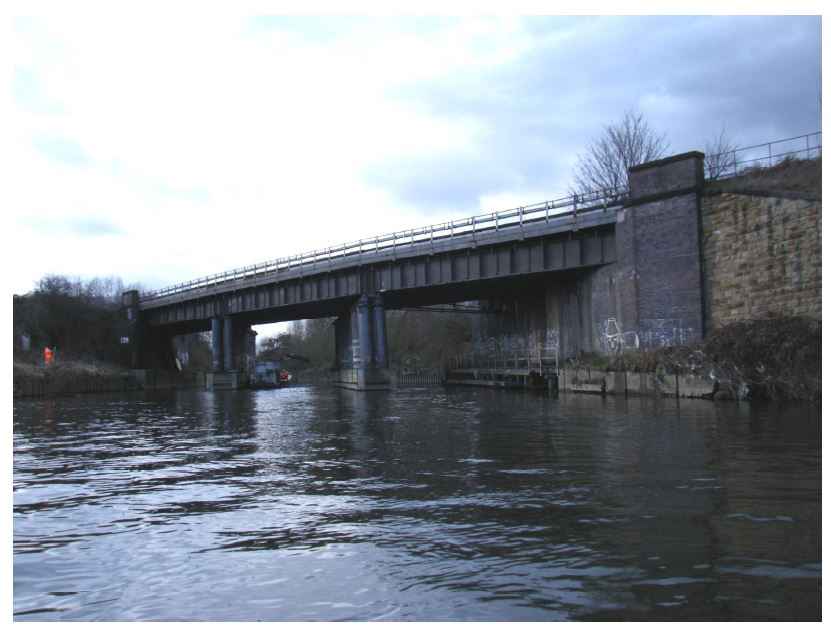

Location: Conisbrough, Doncaster

Clients: Spence

Scope of Services: Project Management & Lead Design, Structural Engineering, Civil Engineering, Rail Engineering, Temporary Works

Project Summary

As part of the nationwide Network Rail Access For All programme to improve accessibility at train stations, VEDA Associates were appointed by Spence as lead designer to deliver the GRIP 5 multi discipline detailed design at Blackhorse Station. The scheme involved the proposed part removal of the existing non-compliant precast concrete high level access walkway from the existing LUL station and the design of a new 1:20 DDA complaint steel walkway, which was to provide access to the existing over bridge. The scheme also involved the implantation of two lifts, one on each platform, which again is to provide step free access to the existing overbridge.

Based on the suspicion that the structure’s river caissons were sinking, VEDA was contracted to devise a process for probing a pier and the depths below. Electromagnetic investigation of the structure failed to produce reliable depression parameters however, adaption of the bridge from four to three tracks had left an original caisson relatively free from track infrastructure.

VEDA decided that boring this structure would give access to the foundational material, which could then be probed for accurate and relevant data. VEDA Engineer Jack Edwards specified the elements and materials for a bespoke steel support platform with six diagonal struts to support a GEO 205 Commachio drilling rig to core the caisson.

The steel 4m by 8m platform was clamped to the caisson.

Once the platform was in place and the coring rig lifted onto the platform using a crane, recovery of samples from below the pier was possible. Samples were also collected using a bore hole method in the vicinity. The results from the coring were provided to NR, who are now in a position to formulate a suitable maintenance or replacement strategy for the bridge.

The design process for the rig platform was completed in four weeks, with the associated onsite work taking two weeks. To ensure the vital protection of the watercourse below the rig platform, a protective membrane was added to its boarding to prevent drilling fluid spillage.